How Industrial Scales Enhance Safety and Precision in Bulk Weighing Applications

How Industrial Scales Enhance Safety and Precision in Bulk Weighing Applications

Blog Article

Why to Pick Industrial Scales for Accurate Weight Dimension in Various Industries

In an age where accuracy is paramount, the choice of commercial ranges for accurate weight dimension plays a crucial function throughout varied industries. These ranges not only enhance functional efficiency however additionally guarantee compliance with regulative criteria, influencing every little thing from production to shipping.

Significance of Accurate Weight Dimension

In the world of industrial operations, the value of precise weight dimension can not be overemphasized. Exact weight measurement is fundamental across various sectors, influencing both functional effectiveness and item quality - Industrial Scales. It works as an essential consider inventory monitoring, guaranteeing that products are effectively represented, therefore minimizing waste and reducing expenses

In manufacturing, precise weight dimension directly impacts production procedures. Abnormalities in weight can result in ineffective products or extreme resource allowance, affecting total productivity. Additionally, in markets such as drugs and food manufacturing, adherence to rigorous weight requirements is essential for regulatory conformity and consumer safety.

Furthermore, precise weight measurements promote effective logistics and supply chain management. Correctly evaluated shipments ensure that transport expenses are enhanced which stock degrees are maintained accurately, thus stopping stock lacks or overstock scenarios.

Kinds Of Industrial Scales

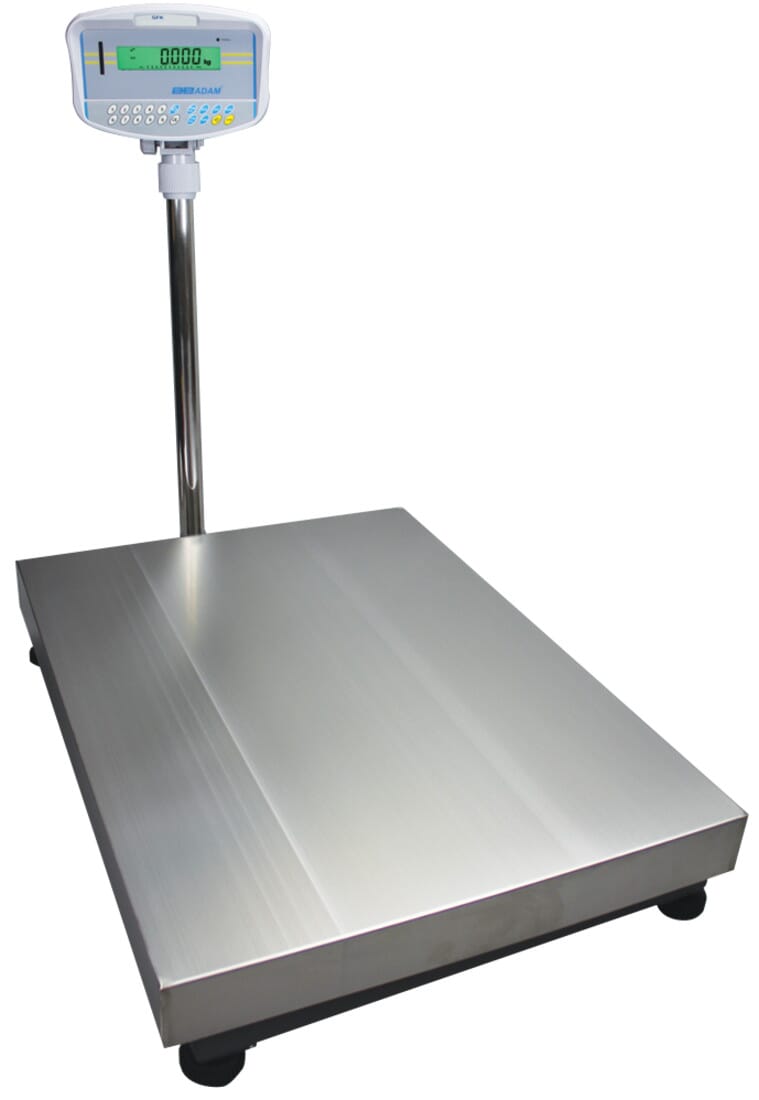

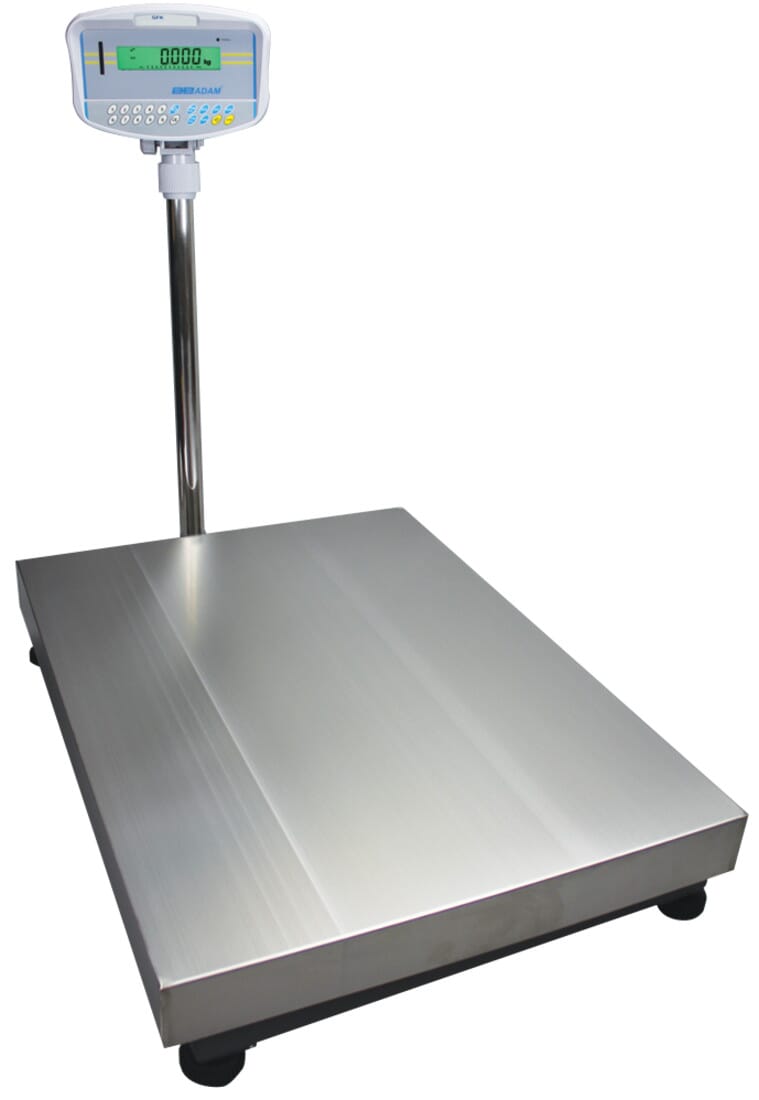

A wide array of commercial scales are offered, each created to fulfill certain dimension needs across diverse industries. Common kinds include floor ranges, which are suitable and durable for weighing big items or pallets in stockrooms and circulation. Bench scales are smaller and perfect for lighter materials, commonly made use of in retail setups or making for specific part control.

One more category is mobile ranges, which provide the versatility to be moved easily around job websites, making them excellent for field operations or temporary setups. Precision ranges, on the other hand, are created for high precision and are frequently used in laboratories and high quality control atmospheres.

Tons cells are crucial parts in numerous industrial scales, transforming push into an electrical signal for precise analyses. In addition, truck scales offer the methods to weigh heavy lorries and their tons, ensuring compliance with guidelines and optimizing logistics.

Last but not least, checkweighers immediately contrast the weight of products versus preset limits, boosting top quality guarantee in assembly line (Industrial Scales). Each kind of industrial range offers an one-of-a-kind function, dealing with the certain needs of sectors such as manufacturing, logistics, food processing, and pharmaceuticals

Benefits of Using Industrial Scales

Regularly using industrial scales provides considerable benefits throughout numerous fields. Among the main benefits is enhanced precision in weight dimension, which is essential for maintaining high quality standards and regulative compliance. Exact dimensions avoid pricey mistakes in production, shipping, and inventory management, ultimately leading to enhanced operational performance.

In addition, industrial ranges are designed for resilience and robustness, allowing them to endure harsh settings usually found in production and warehousing. This resilience makes sure a long life expectancy, decreasing the demand for regular substitutes and maintenance prices.

In addition, using industrial scales improves safety and security and decreases waste. By guaranteeing that products are evaluated properly, firms can prevent straining vehicles, which can lead to mishaps and penalties.

Applications Across Different Industries

Industrial scales play an essential function in various industries, including manufacturing, logistics, food processing, and drugs. In production, these ranges are necessary for making certain that raw materials are determined properly, thereby keeping product quality and uniformity (Industrial Scales). Accuracy in weight measurement directly impacts manufacturing effectiveness and cost management

In logistics, commercial scales assist in the precise weighing of deliveries, which is critical for sticking to optimizing and delivering guidelines freight costs. Precise weight data aids simplify operations and improves supply chain administration.

The food processing sector depends heavily on commercial ranges for compliance with wellness and security laws. They are made use of to evaluate ingredients specifically, making sure that formulas satisfy click here for more both quality criteria and legal requirements. This is important not only for customer security but likewise for preserving brand honesty.

Pharmaceutical firms use industrial ranges to make sure accurate does in medication manufacturing, where also the smallest deviation can have substantial effects. Compliance with rigorous regulative standards makes specific weight measurement critical in this sector.

## Factors to Take Into Consideration When Selecting Ranges

Picking the right range for particular applications calls for mindful factor to consider of several variables. The ability of the scale is essential; it has to accommodate the official site optimum weight of the products being measured without surpassing its limitations. In addition, the readability, or tiniest increment the range can precisely show, is essential for accuracy, particularly in industries where weight inconsistencies can result in substantial economic losses or security issues.

Ecological conditions also play a considerable role in range choice. For instance, scales used in humid or harsh environments might need specific materials to ensure toughness. Similarly, mobility may be crucial in particular applications, demanding light-weight and battery-operated versions.

Conclusion

In final thought, the selection of commercial scales is critical for making certain accurate weight measurement across diverse markets. Their capacity to provide accurate readings not only improves functional performance yet likewise supports governing conformity and stock monitoring. The adaptability and durability of these scales facilitate their application in different sectors, eventually adding to set you back decrease and improved product high quality. Therefore, spending in high-quality industrial scales is essential for organizations intending to maximize and maintain high standards earnings.

Report this page